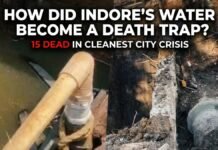

Indore: Indore city has maintained its highest position in the field of cleanliness. Now the unimaginable idea of making energy from waste has been embodied in Indore. In order to realize Prime Minister Shri Narendra Modi’s concept of Waste-to-Wealth and to innovate in the field of sanitation, Municipal Corporation, Indore has set up a Bio-CNG Plant of 550 MT per day capacity for wet waste disposal. Has been done. This plant is the largest and the first plant of Bio-CNG from organic waste in the entire Asia continent, which is a matter of pride not only for Indore but for the state as well as for the country. This Bio-CNG is located at Devguradiya Trenching Ground in the city. Prime Minister Shri Narendra Modi will inaugurate the plant. Chief Minister Shri Shivraj Singh Chouhan will also attend the program.

Bio CNG Plant PPP model is based. On the one hand, the Municipal Corporation, Indore does not have to bear any financial burden on the establishment of this plant, on the other hand, the agency that set up the plant, IEISL, New Delhi will pay a premium of Rs. 2.5 crore per annum to the Municipal Corporation, Indore. Will be given In this plant, 550 MT of wet waste (domestic organic waste) will be treated daily, which will generate 17 thousand 500 kg of Bio-CNG. Gas and 100 tonnes of high-quality organic compost will be produced. Bio-CNG is produced from this plant. Out of this, 50 percent gas will be available to Municipal Corporation, Indore for the use of public transport buses. The remaining 50 percent of gas can be sold to various industrial and commercial consumers.

West Segregation Best Quality

Since the waste segregation of Indore city is of good quality, it has been decided to set up this plant in Indore. Before the decision to set up the plant, the said company got the wet waste tested by taking more than 200 samples in the last year. Based on the test results, it was revealed that only 0.5 to 0.9 percent of the rejects are available in the wet waste, which was found to be of high quality as compared to other European countries.

Pre-treatment

After a source-based segregation process, it is necessary to preprocess it to produce biogas from organic waste. For this, state-of-the-art equipment is required in the plant. Since the organic waste collected from Indore city has very less amount of inorganic material, this waste has to go through the processing process. For this, state-of-the-art and automatic equipment have been installed inside the plant. After receiving the organic waste in a bunker, it is transported to the processing equipment with the help of a grab crane. Inorganic and fibrous substances from organic waste are separated by a large screen. Recycled water is mixed in appropriate proportion in the organic solid waste, which produces slurries of appropriate quality. In the separation hammer mill, the inorganic material is separated by the self-propelled method. Its control is computerized.

Bio Methanation Process

Organic waste undergoes a decomposition process for about 25 days in the absence of oxygen. This process is called the bio-methanation process, in which micro-organisms contribute a lot. These micro-organisms complete the process of biological decomposition at a controlled temperature. Biogas is produced in the form of energy in this process. State-of-the-art CSTR at this plant set up in Indore city. Digester tanks based on mesophilic technology were manufactured. Heat exchangers for temperature control and center mixers to maintain slurry uniformity have been installed in these tanks, which have been imported from European countries.